In the world of display technology, few components are as ubiquitous and critical as the TFT LCD module. As an industry expert with years of experience, I often find that while the term is commonly used, its full meaning, construction, and advantages are not always deeply understood. This article provides a comprehensive look into what precisely a TFT LCD module is, how it functions, and why it remains a dominant force across countless applications.

Defining the Core: TFT and LCD

To understand a TFT LCD module, we must first break down the acronym.

- LCD (Liquid Crystal Display): An LCD is a flat-panel display that uses the light-modulating properties of liquid crystals. These crystals do not emit light directly; instead, they act as shutters, controlling the passage of a backlight to create an image.

- TFT (Thin-Film Transistor): This is the active matrix technology that makes modern, high-quality LCDs possible. A TFT is a special type of transistor fabricated onto a glass substrate. In a display, each pixel (the smallest point of light) is controlled by one to four of these tiny transistors.

Therefore, a TFT LCD is an “active matrix” LCD where each pixel is actively controlled by its own dedicated transistor, leading to superior image quality, faster response times, and better contrast compared to older, passive-matrix technologies.

The Complete Anatomy of a TFT LCD Module

A TFT LCD module is more than just the glass panel. It is a fully integrated assembly, ready to be connected to a host system. The key components of a standard TFT LCD module include:

- TFT Glass Panel (Cell): This is the heart of the module. It contains the layers of liquid crystals sandwiched between two glass substrates, with the matrix of thin-film transistors deposited on one.

- Backlight Unit (BLU): Since LCDs do not produce their own light, a backlight is essential. This is typically composed of LEDs (Light Emitting Diodes) that provide uniform, bright white light across the entire screen.

- Driver ICs (Integrated Circuits): These chips are the “translators.” They take the low-voltage digital signals from your device’s main processor (like a Raspberry Pi or microcontroller) and convert them into the precise voltages and timing sequences required to control each individual pixel on the TFT glass panel.

- Printed Circuit Board (PCB): The driver ICs and other supporting electronics are mounted on a flexible or rigid PCB. This board hosts the interface connectors.

- Interface Connectors: These are the physical ports for connecting the TFT LCD module to the host system. Common interfaces include:

- LVDS (Low-Voltage Differential Signaling): Common in high-resolution displays like laptops and monitors.

- eDP (Embedded DisplayPort): The modern successor to LVDS.

- RGB/MCU Interface: Often used in smaller, embedded systems and industrial controls.

- MIPI DSI (Mobile Industry Processor Interface Display Serial Interface): Prevalent in smartphones and compact mobile devices.

- Metal or Plastic Frame: This structural frame holds all the components together securely, protecting the delicate glass from physical stress.

Why TFT LCD Module Technology Dominates

The widespread adoption of TFT LCD module technology is no accident. Its advantages are clear and proven:

- High Image Quality: Active matrix technology enables high resolution, excellent color reproduction, and sharp contrast.

- Cost-Effectiveness: Mature manufacturing processes have made TFT LCD modules highly economical at scale.

- Versatility and Scalability: This technology can be scaled from tiny wearable displays under 1 inch to massive television screens exceeding 100 inches.

- Reliability and Longevity: With no moving parts and solid-state construction, a well-built TFT LCD module offers a long operational lifespan.

- Low Power Consumption: Especially with LED backlighting, TFT LCD modules are highly efficient, making them ideal for battery-powered portable devices.

Key Applications of TFT LCD Modules

The application of TFT LCD modules is virtually limitless. You interact with them dozens of times a day:

- Consumer Electronics: Smartphones, tablets, laptops, desktop monitors, and televisions.

- Industrial and Human-Machine Interface (HMI): Control panels for factory automation, medical equipment displays, and test & measurement instruments.

- Automotive: Center console infotainment systems, digital instrument clusters, and rear-seat entertainment displays.

- Medical: High-brightness, high-contrast displays for diagnostic imaging and patient monitoring systems.

- Retail and Point-of-Sale (POS): Payment terminals, digital signage, and kiosks.

The Future and Competing Technologies

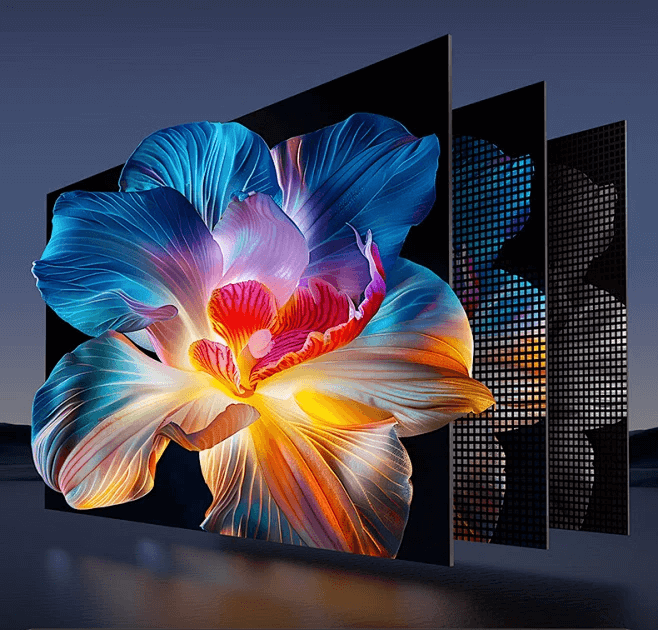

While newer technologies like OLED (Organic Light-Emitting Diode) offer superior contrast ratios and flexibility, the TFT LCD module market continues to thrive and innovate. Advancements like Mini-LED backlighting, which uses thousands of tiny LEDs for precise local dimming, are allowing TFT LCDs to close the performance gap with OLED in terms of contrast, while retaining their cost and longevity advantages for many applications.

Conclusion

In summary, a TFT LCD module is a sophisticated, self-contained display system that combines a thin-film transistor active matrix with a liquid crystal cell, a backlight, and integrated drive electronics. Its role as the visual interface for the digital world is firmly entrenched due to its proven performance, economic viability, and relentless innovation. For engineers, designers, and businesses, understanding the fundamentals of the TFT LCD module is essential for selecting the right display solution for any project. When you require a reliable, high-quality, and cost-effective display, the TFT LCD module remains an unparalleled choice.